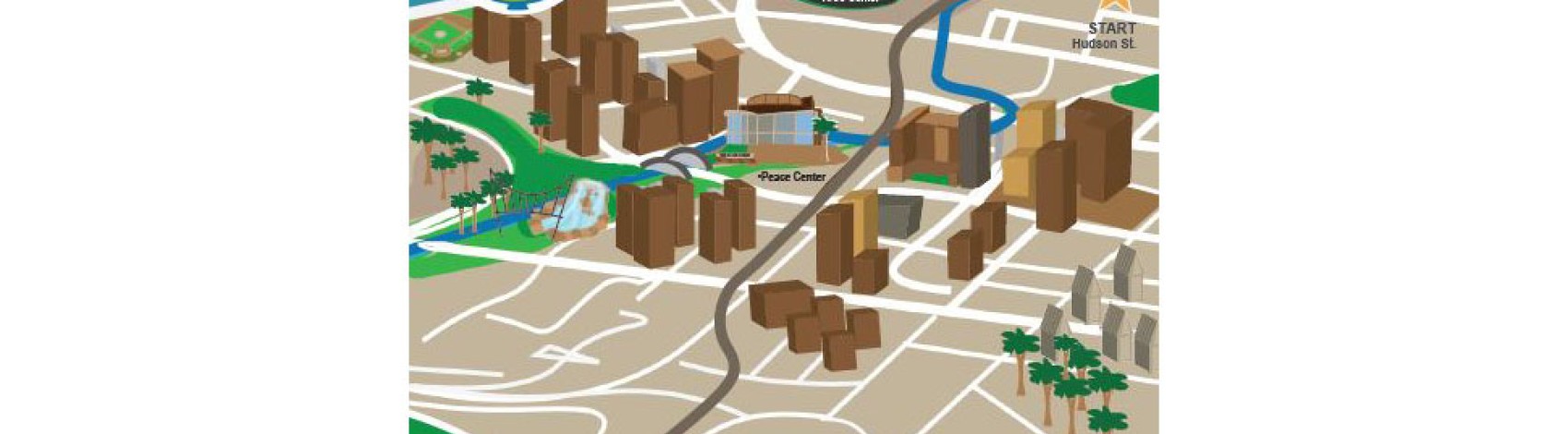

DIG Greenville, a wastewater conveyance project by Renewable Water Resources (ReWa), will address some of Greenville County’s 100-year sewage needs. The project will involve the construction of a gravity sewer tunnel 100 feet below ground. It will span from Hudson Street to Cleveland Park in Greenville, SC. Graphic courtesy of ReWa

The Client

Bunnell-Lammons Engineering, Inc.

The Challenge

DIG Greenville is a wastewater conveyance project that will address some of Greenville County, South Carolina’s sewage needs for the next 100 years. When constructed, it will feature a 10-feet diameter, 7,000-feet long gravity sewer tunnel bored through rock approximately 100 feet below downtown Greenville. Drilling the tunnel through rock will result only in surface impact at either end of the tunnel. If conventional cut-and-cover methods were to be used, the entire sewer route would sustain surface impacts.

The project site is located in the Piedmont Physiographic Province. As typical for the Piedmont, the profile of the partially weathered rock and hard rock is quite irregular and erratic, even over short horizontal distances. Weathering is facilitated by fractures, joints, and the presence of less resistant rock types. Designing and constructing tunnels through these types of rock formations can present some very complex technical challenges, and detailed investigations of rock and fracture characteristics are necessary for a successful project.

Gel Engineering Services Provided

GEL Solutions provided geophysical borehole logging services in a total of 14-vertical and inclined boreholes to study in detail the bedrock and bedrock fractures along the route. The geophysical logging equipment consisted of Acoustic Televiewer and Optical Televiewer. The televiewer logs were used to determine depth, dip, strike and aperture of fractures, as well as fracture zones in open-hole segments of the borings. Other details about the fractures such as fracture infills and rock discoloration were also noted. Rock discoloration is typically caused by water flowing through fracture systems.

The Results

The Acoustic and Optical Televiewer data, as well as the results from an array of laboratory tests incorporated into the exploration program, were used for evaluating, selecting, and predicting the performance of a Tunnel Boring Machine to be used for constructing the tunnel.

Get In Touch

How we can help you solve your unique challenge with our breadth of expert services.